ct-3-s instructions

- by cooper

CT-3-S‚ often representing cable tray systems‚ facilitates organized electrical cable routing and maintenance. These open metal structures‚ like CT 400X200‚ support cabling.

In medical contexts‚ CT signifies Computed Tomography‚ utilizing X-rays to create detailed cross-sectional images for diagnostic purposes‚ aiding in precise analysis.

What is CT-3-S?

CT-3-S embodies a versatile designation‚ shifting context between electrical engineering and medical imaging. Within electrical installations‚ it predominantly signifies a “” (cáo shì qiáo jià) – a cable tray or cable ladder system. These are open-profile metal frameworks designed to support and route electrical cabling‚ simplifying installation and ongoing maintenance procedures. A common specification‚ like CT 400X200‚ denotes a tray with a 400mm width and 200mm height.

Conversely‚ in the medical field‚ CT stands for Computed Tomography. This advanced imaging technique employs X-rays to generate detailed cross-sectional images of the body. The fundamental principle involves rotating an X-ray source and measuring the intensity of the transmitted radiation‚ which is then computationally reconstructed into 2D and 3D visualizations. This allows clinicians to visualize internal structures with remarkable clarity‚ aiding in diagnosis and treatment planning. The system comprises components like the scanner gantry‚ scanning bed‚ computer system‚ and control console.

Common Applications of CT-3-S

In electrical engineering‚ CT-3-S‚ representing cable tray systems‚ finds widespread application in commercial and industrial settings. These systems are crucial for organizing and supporting extensive cable runs in power distribution‚ control systems‚ and data communication networks. They ensure safe and efficient cable management‚ reducing the risk of damage and facilitating easy access for maintenance and upgrades. Common installations include power plants‚ factories‚ data centers‚ and large office buildings.

Within medical imaging‚ CT (Computed Tomography) scans are indispensable diagnostic tools. They are routinely used to detect a vast range of conditions‚ including internal injuries‚ cancers‚ cardiovascular diseases‚ and infectious diseases. Specific applications include brain scans for stroke detection‚ chest scans for lung abnormalities‚ and abdominal scans for organ evaluation. Radiation exposure is a consideration‚ typically around 2-10mSv per scan‚ adhering to established safety standards. The technology’s ability to create detailed 3D images makes it invaluable for surgical planning and guiding minimally invasive procedures.

Understanding the Components of CT-3-S

CT-3-S systems‚ whether cable trays or medical scanners‚ comprise core materials like metal frameworks and sophisticated components. X-ray tubes‚ detectors‚ and computer systems are vital.

Core Materials Used in CT-3-S Construction

CT-3-S construction relies heavily on robust materials‚ differing based on application. For cable tray systems‚ galvanized steel is prevalent due to its strength‚ corrosion resistance‚ and cost-effectiveness. Aluminum alloys offer a lighter-weight alternative‚ suitable for applications where weight is a critical factor‚ though generally more expensive.

Stainless steel is employed in environments demanding exceptional corrosion protection‚ such as coastal areas or industrial facilities with harsh chemical exposure. Polymer materials‚ like PVC or fiberglass‚ provide electrical insulation and are used for specialized cable tray applications.

Conversely‚ medical CT scanners utilize materials optimized for X-ray interaction. The gantry‚ housing the X-ray tube and detectors‚ incorporates dense materials like lead for radiation shielding. High-density alloys are used in the detector arrays to efficiently capture X-ray photons. The scanner bed is constructed from materials capable of supporting patient weight and precise movement. Computer systems rely on standard electronic components and robust housings for operational reliability.

Key Functional Parts of the System

For CT-3-S cable tray systems‚ key components include the tray itself – available in various depths and widths – supporting brackets for secure mounting‚ and connectors for joining sections. Splice plates ensure structural integrity‚ while covers provide cable protection and maintain a neat appearance. Accessories like cable ties and dividers aid in organization.

In medical CT scanners‚ the core components are significantly more complex. The X-ray tube generates the radiation beam‚ while the detector array captures the transmitted X-rays. The gantry rotates these components around the patient. A high-performance computer system reconstructs the raw data into cross-sectional images.

The control console allows operators to manage scan parameters and view images. The scanning bed precisely positions the patient. Power distribution units provide stable electrical supply. Finally‚ sophisticated software manages data acquisition‚ image processing‚ and display‚ ensuring accurate diagnoses.

CT-3-S in Electrical Installations

CT-3-S‚ as cable tray‚ supports electrical wiring‚ enabling organized cable runs. In diagrams‚ “CT” denotes cable tray installation‚ simplifying cable pathway representation for installers.

CT as Cable Tray (Electrical)

CT-3-S‚ when utilized as a cable tray in electrical installations‚ functions as an open metal structure meticulously designed to support and guide electrical cables along a defined path. This system significantly simplifies cable laying and ongoing maintenance procedures‚ offering a robust and accessible solution for managing complex wiring configurations.

The designation “CT 400X200‚” for instance‚ specifies a cable tray with a width of 400 millimeters and a height of 200 millimeters‚ providing a standardized dimension for project planning and material procurement. These trays are commonly employed in both industrial and commercial settings‚ ensuring efficient and safe cable distribution.

Employing cable trays like CT-3-S enhances accessibility for inspections‚ modifications‚ and repairs‚ reducing downtime and maintenance costs. Furthermore‚ they contribute to improved safety by preventing cable damage and minimizing the risk of electrical hazards. Proper installation and adherence to relevant electrical codes are crucial for optimal performance and longevity of the system.

CT in Electrical Diagrams ⎼ Meaning and Usage

In electrical diagrams‚ “CT” commonly denotes cable tray routing‚ indicating that cables are laid and supported along a cable tray system. This notation streamlines the visual representation of complex wiring layouts‚ providing a clear understanding of cable pathways for installers and maintenance personnel.

Alongside “CT”‚ other abbreviations frequently appear‚ defining cable installation methods. “CE” signifies cable installation along the ceiling‚ indicating overhead routing. “WE” denotes wall-mounted‚ exposed cabling‚ while “WC” represents concealed wiring within walls. “CC” specifies cabling within the ceiling cavity.

Understanding these designations is crucial for accurate interpretation of electrical schematics. For example‚ “WDZN-BYJ (3X2.5)‚ FB-2‚ CT; SC20‚ WC‚ CC” details specific cable types‚ quantities‚ and installation methods. Correctly deciphering these codes ensures proper installation and adherence to safety regulations‚ preventing potential electrical hazards and ensuring system reliability.

CT-3-S and Medical Imaging (Computed Tomography)

CT‚ or Computed Tomography‚ employs X-rays and computer processing to generate detailed cross-sectional images of the body‚ aiding in accurate diagnoses.

CT as Computed Tomography ⎼ An Overview

Computed Tomography (CT)‚ frequently abbreviated as CT‚ represents a pivotal diagnostic imaging technique within modern medicine. Unlike traditional X-rays which provide two-dimensional images‚ CT scanning utilizes X-rays in conjunction with sophisticated computer processing to generate detailed‚ cross-sectional images – essentially‚ slices – of the body.

This process allows medical professionals to visualize internal organs‚ bones‚ soft tissues‚ and blood vessels with remarkable clarity. The fundamental principle revolves around rotating an X-ray source around the patient‚ capturing numerous images from various angles. These projections are then mathematically reconstructed by a computer to create a comprehensive three-dimensional representation.

While often referred to simply as “CT‚” it’s crucial to understand that the technology extends beyond just X-ray based imaging. Any system capable of creating cross-sectional images through data acquisition and computer reconstruction can technically be classified as CT. However‚ in clinical practice‚ “CT” generally refers to X-ray Computed Tomography.

The resulting images are invaluable for diagnosing a wide spectrum of conditions‚ from detecting fractures and internal bleeding to identifying tumors and assessing the extent of disease. CT scans are a cornerstone of emergency medicine and play a vital role in treatment planning.

How CT Scans Work: The Basic Principles

CT scanning operates on the principle of measuring X-ray attenuation – how much radiation is absorbed as it passes through different tissues within the body. A rotating X-ray tube emits a beam of radiation that traverses the patient. Detectors positioned opposite the tube measure the amount of radiation that emerges.

Different tissues absorb varying amounts of X-rays; dense materials like bone absorb more‚ appearing brighter on the image‚ while softer tissues like organs absorb less‚ appearing darker. As the X-ray tube rotates‚ numerous projections are acquired from multiple angles.

These projections aren’t directly interpretable as images. Instead‚ they are fed into a powerful computer that employs complex mathematical algorithms – primarily filtered back projection – to reconstruct a cross-sectional image. This reconstruction process essentially “slices” the body into thin sections‚ revealing internal structures.

The resulting images are displayed on a monitor‚ allowing radiologists to examine the anatomy in detail. By stacking these slices‚ a three-dimensional representation of the scanned area can be created‚ providing a comprehensive view of the internal structures.

CT Scan Data Acquisition Process

Data acquisition in CT scanning begins with the patient positioned on a motorized table that moves through the scanner’s gantry – the circular opening housing the X-ray tube and detectors. The X-ray tube rotates continuously around the patient‚ emitting a focused beam of radiation.

As the tube rotates‚ detectors measure the intensity of the X-rays after they’ve passed through the patient’s body. These detectors convert the X-ray energy into electrical signals‚ which are then digitized and sent to the computer system. The speed of the gantry rotation and table movement significantly impacts scan time and image quality.

Modern CT scanners utilize multiple detector rows‚ allowing for the simultaneous acquisition of data from multiple slices. This helical or spiral scanning technique reduces scan time and minimizes motion artifacts. The raw data collected consists of a series of projections‚ representing the X-ray attenuation at various angles.

This raw data is then processed using sophisticated reconstruction algorithms to create the final CT images. The entire process‚ from initial positioning to image reconstruction‚ is carefully controlled and monitored by trained technologists.

CT-3-S: Electrical Cable Management

CT-3-S systems‚ like the CT 400X200‚ provide robust cable support‚ ensuring organized and safe electrical installations. They simplify cable laying and future maintenance tasks.

CT-400X200: Dimensions and Specifications

CT-400X200 designates a specific cable tray dimension‚ indicating a width of 400 millimeters and a height of 200 millimeters. This standardized sizing allows for efficient cable organization within electrical installations. These cable trays‚ constructed from metal‚ provide a robust and open framework for supporting and guiding electrical cables.

The ‘CT’ designation itself signifies “” in Chinese‚ translating to slotted bridge or cable tray. This highlights its primary function: creating a defined pathway for cables‚ simplifying both initial installation and ongoing maintenance procedures. The specific dimensions‚ 400×200‚ are crucial for planning cable routes and ensuring adequate space for the intended cable load.

While detailed material specifications may vary depending on the manufacturer‚ CT-400X200 trays are generally made from steel or aluminum‚ offering strength and durability. Load capacity will depend on the material and construction‚ requiring careful consideration during installation to prevent overloading and ensure safety. Proper selection and installation of CT-400X200 trays are essential for reliable electrical system performance.

Benefits of Using CT for Cable Support

Employing cable trays (CT) for cable support offers significant advantages in electrical installations. Primarily‚ CT systems‚ like the CT-400X200‚ provide a neat and organized cabling pathway‚ simplifying maintenance and troubleshooting. This open design facilitates easy access for modifications‚ additions‚ or repairs‚ reducing downtime and associated costs.

Compared to conduit systems‚ cable trays generally offer greater flexibility in accommodating future cable additions. The open structure allows for easy rerouting or expansion without the need for extensive rework. Furthermore‚ CT systems enhance safety by protecting cables from physical damage and reducing the risk of short circuits.

Properly installed cable trays also contribute to improved airflow‚ which can be crucial for heat dissipation in densely populated cable runs. This helps prevent overheating and extends the lifespan of the cables. Utilizing CT systems streamlines electrical projects‚ promoting efficiency and long-term reliability within the installation.

Safety Considerations with CT-3-S

CT scans involve radiation exposure‚ typically 2-10mSv per scan‚ within established safety limits (50mSv annually for workers). Adherence to regulations is crucial.

Radiation Exposure in Medical CT Scans

Computed Tomography (CT) scans utilize X-rays‚ inherently involving radiation exposure to patients. While essential for diagnosis‚ understanding the associated risks is paramount. The radiation dose received during a typical CT scan generally ranges from approximately 2 to 10 millisieverts (mSv). This level is considered relatively low when compared to the annual radiation dose limit established for radiological workers‚ which is 50 mSv.

However‚ it’s crucial to acknowledge that cumulative radiation exposure over a lifetime can increase the risk of developing cancer. Therefore‚ CT scans should only be performed when medically necessary and justified by a clear clinical indication. Healthcare professionals strive to minimize radiation dose through techniques like adjusting scan parameters and utilizing shielding where appropriate.

The amount of radiation varies depending on the body part being scanned; some areas are more sensitive than others. Patients should openly discuss any concerns regarding radiation exposure with their physician before undergoing a CT scan‚ ensuring informed consent and a balanced assessment of benefits versus risks.

Safety Standards and Regulations for CT Equipment

CT equipment operates under stringent safety standards and regulations to protect both patients and operators. These guidelines encompass radiation safety‚ electrical safety‚ and mechanical safety protocols. Regulatory bodies establish permissible radiation dose limits and mandate regular quality control checks to ensure equipment accuracy and performance.

Manufacturers are required to adhere to specific design and manufacturing standards‚ including shielding requirements to minimize radiation leakage. Healthcare facilities must implement comprehensive radiation safety programs‚ including staff training‚ dose monitoring‚ and regular equipment maintenance. Compliance with these regulations is routinely assessed through inspections and audits.

Furthermore‚ standards govern the proper disposal of radioactive materials and the management of medical waste. Continuous advancements in CT technology focus on dose reduction techniques‚ such as iterative reconstruction algorithms and automatic exposure control‚ further enhancing patient safety and minimizing potential risks associated with radiation exposure.

Decoding Electrical Wiring Designations

WDZN-BYJ (3X2.5) signifies halogen-free‚ low-smoke‚ flame-retardant wiring. CT denotes cable tray installation‚ while CE indicates ceiling-mounted cable routing within electrical diagrams.

WDZN-BYJ (3X2.5)‚ FB-2‚ CT; SC20‚ WC‚ CC ⎻ Explained

WDZN-BYJ (3X2.5) is a specific electrical wire designation. “WDZN” indicates a wire that is halogen-free‚ low smoke‚ flame-retardant‚ and fire-resistant‚ prioritizing safety by minimizing toxic fumes during a fire. “BYJ” further specifies the wire’s characteristics‚ while “(3X2.5)” denotes the wire’s construction – three conductors‚ each with a 2.5 square millimeter cross-sectional area.

FB-2 likely refers to a specific type of flexible conduit or cable protection system‚ offering mechanical protection to the wires. Following this‚ CT‚ within this context‚ signifies that the wiring is installed within a cable tray system‚ a common method for organized cable management.

SC20 likely represents a specific component or specification related to the cable tray or its accessories. WC denotes wiring along a wall‚ indicating a surface-mounted installation. Finally‚ CC signifies concealed conduit‚ meaning the wiring is hidden within a wall or ceiling‚ providing a neat and protected installation.

Understanding these designations is crucial for accurate electrical installation‚ maintenance‚ and troubleshooting‚ ensuring compliance with safety standards and efficient system operation.

CE‚ WE‚ and CC in Electrical Schematics

In electrical diagrams‚ CE signifies cable installation along the ceiling‚ specifically indicating that wiring is routed above the suspended ceiling or directly on the ceiling surface. This method is common for distributing power and communication cables throughout a building‚ offering accessibility for maintenance.

Conversely‚ WE denotes wiring along the wall‚ meaning cables are installed on the surface of the wall‚ exposed and readily visible. This approach is often used in industrial settings or where easy access for modifications is required. It’s a straightforward installation method‚ but may require additional protection.

CC represents concealed conduit‚ indicating that the wiring is hidden within the walls‚ floors‚ or ceilings. This provides a neat and protected installation‚ enhancing aesthetics and safeguarding cables from physical damage. It requires more effort during installation but offers long-term benefits.

These notations are essential for interpreting electrical schematics accurately‚ ensuring correct installation and facilitating efficient troubleshooting. Understanding these symbols is vital for electricians and anyone involved in electrical work.

CT-3-S System Architecture

CT systems comprise a scanning gantry‚ patient bed‚ computer system‚ and control console. X-ray tubes‚ filters‚ and collimators are key components within the scanning mechanism.

Scanning System Components

The scanning system‚ central to CT-3-S functionality‚ meticulously gathers data for image reconstruction. At its core lies the X-ray tube‚ generating the radiation necessary to penetrate the patient’s body. Crucially‚ a filter modulates the X-ray beam‚ optimizing its quality and reducing unnecessary radiation exposure. Following the filter‚ a collimator precisely shapes the beam‚ focusing it onto the targeted anatomical area.

Detectors‚ positioned opposite the X-ray tube‚ capture the attenuated X-ray photons after they’ve traversed the patient. These detectors convert the radiation into electrical signals‚ which are then processed to determine the X-ray’s intensity at various points. The gantry‚ a rotating structure‚ houses the X-ray tube and detectors‚ enabling data acquisition from multiple angles. This rotational scanning is fundamental to creating cross-sectional images.

Furthermore‚ the scanning bed precisely positions the patient during the scan‚ ensuring accurate data collection. Sophisticated control systems synchronize the rotation of the gantry with the movement of the bed‚ maintaining consistent image quality throughout the scanning process. The interplay of these components delivers the raw data required for the subsequent image reconstruction phase.

Computer System and Control Console

The computer system serves as the brain of the CT-3-S‚ responsible for processing the raw data acquired by the scanning system and reconstructing it into clinically useful images. Powerful processors and extensive memory are essential for handling the large datasets generated during a scan. Sophisticated algorithms‚ employing techniques like filtered back-projection‚ transform the attenuation data into cross-sectional images.

Image reconstruction isn’t merely about creating a visual representation; it also involves noise reduction and artifact correction to enhance image quality. The system then displays these images on high-resolution monitors‚ allowing radiologists to visualize anatomical structures with remarkable detail. Archiving and storage capabilities are also critical‚ ensuring long-term access to patient scan data.

The control console provides the interface for operators to manage the entire scanning process. Technologists use the console to select scan parameters‚ initiate the scan‚ monitor patient positioning‚ and adjust image reconstruction settings. User-friendly software and intuitive controls are paramount for efficient operation and minimizing errors. This console is the central hub for controlling and monitoring the CT-3-S system.

Related posts:

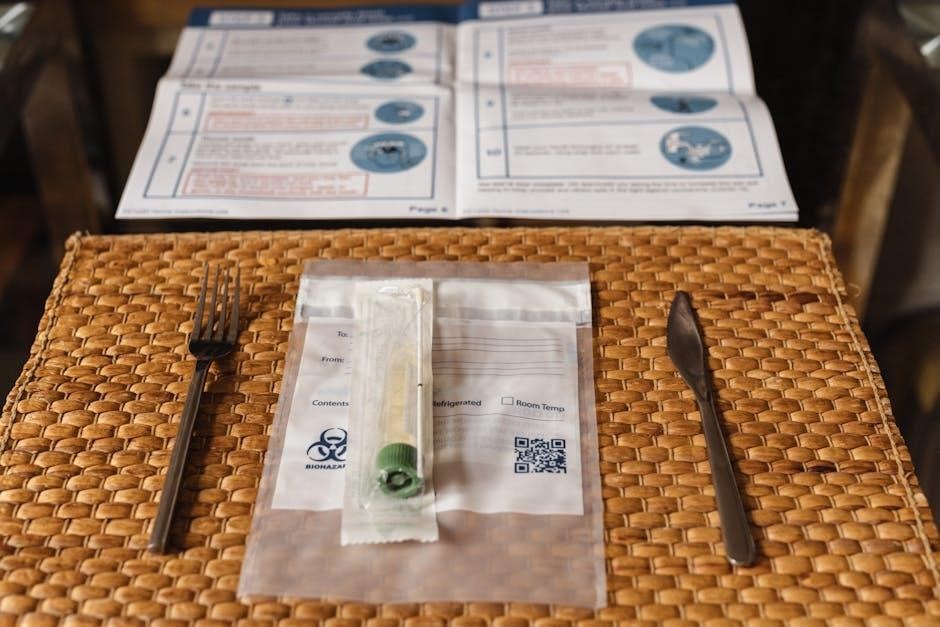

Lost your CT-3S instruction manual? Download a free PDF guide here! Troubleshooting, setup, safety – we’ve got you covered. Get back to using your CT-3S today!

Posted in Instructions